Fiber laser Cutting

‾‾‾‾‾‾‾

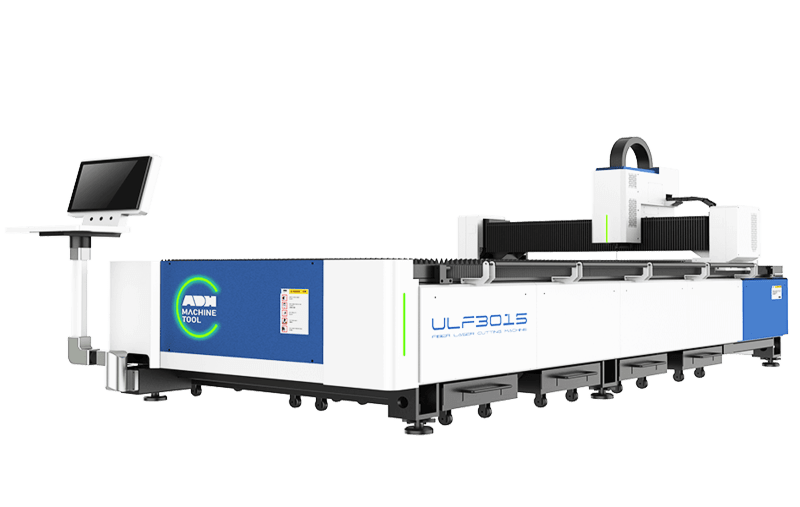

Single Table

ULF Series

The integration of the electric cabinet/laser with the equipment eliminates the need for secondary disassembly and assembly, preventing contamination of optical components and reducing installation time to a mere two hours. Additionally, the modular splicing design allows for straightforward and easy maintenance.

• Laser Power : 1500W/3000W/6000W/12000W

• Cutting range : 3*1.5(m)/4*1.5(m)/6*1.5(m)/4*2(m)/6*2(m)

• Maximum moving speed : 120m/min

• Maximum acceleration : 1.2g

• Positioning accuracy : ±0.05mm

• Repeated positioning accuracy : ±0.02mm

• Operating voltage : 380V/50Hz

• Cooling method : water-cooled

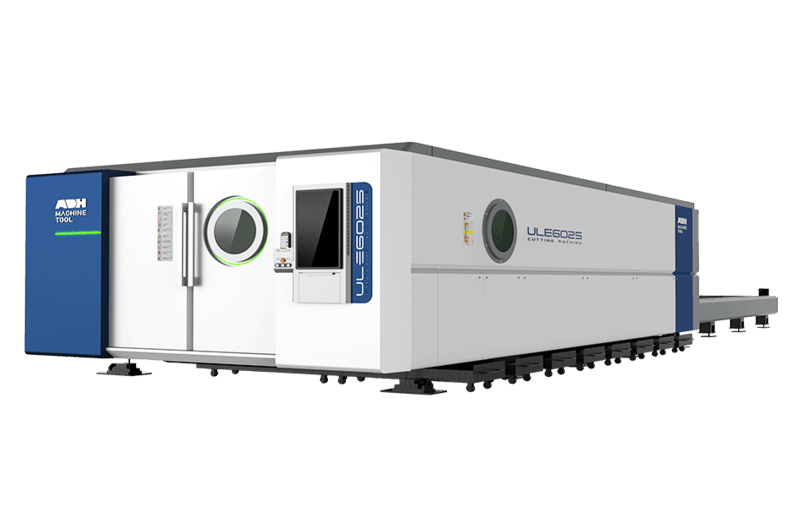

Double Table

ULE Series

The ULE series fiber laser cutter is outfitted with an exchange table and cover, enabling swift table transitions in just 15 seconds. The cutting and feeding processes can be simultaneously executed, resulting in a significant boost in production efficiency.

• Laser Power : 6000W/12000W/15000W/20000W

• Cutting range : 6*2.5(m)/8*2.5(m)/12*2.5(m)

• Maximum moving speed : 150m/min

• Maximum acceleration : 1.5g

• Positioning accuracy : ±0.05mm

• Repeated positioning accuracy : ±0.02mm

• Operating voltage : 380V/50Hz

• Cooling method : water-cooled

Dual-use

ULFT Series

The integrated design enables efficient cutting of both plates and tubes with a single piece of equipment. It provides high precision, fast processing, minimal kerf, smooth sections, user-friendly operation, and low energy consumption. Additionally, it is highly suitable for large-scale continuous processing.

• Laser power : 1500W/3000W/6000W

• Cutting range : 3*1.5(m)/4*1.5(m)/6*1.5(m)/6*2.0(m)/6*2.5(m)

• Maximum size of chuck : 220mm/350mm

• Plate/tube cutting length : 3000mm/4000mm/6000mm

• Maximum moving speed : 90m/min

• Maximum acceleration : 1.2g

• Positioning accuracy : ±0.05mm

• Repeated positioning accuracy : ±0.02mm

• Operating voltage : 380V/50Hz

• Cooling method : water-cooled

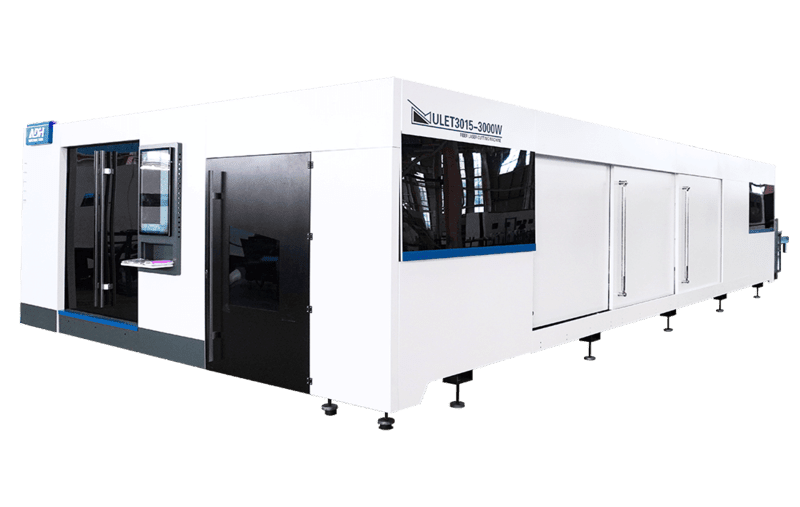

Dual-use with Cover

ULET Series

The design integration for plate and tube cutting is achieved through a single piece of equipment that enables the cutting of flat plates, round pipes, and square pipes with exceptional precision, high velocity, minimal kerf, smooth sections, ease of operation, and low energy consumption. This equipment is well-suited for continuous processing of large quantities.

• Laser power : 1500W/3000W/6000W

• Cutting range : 3*1.5(m)/4*1.5(m)/6*1.5(m)/6*2.0(m)/6*2.5(m)

• Maximum size of chuck : 220mm/350mm

• Plate/tube cutting length : 3000mm/4000mm/6000mm

• Maximum moving speed : 90m/min

• Maximum acceleration : 1.2g

• Positioning accuracy : ±0.05mm

• Repeated positioning accuracy : ±0.02mm

• Operating voltage : 380V/50Hz

• Cooling method : water-cooled

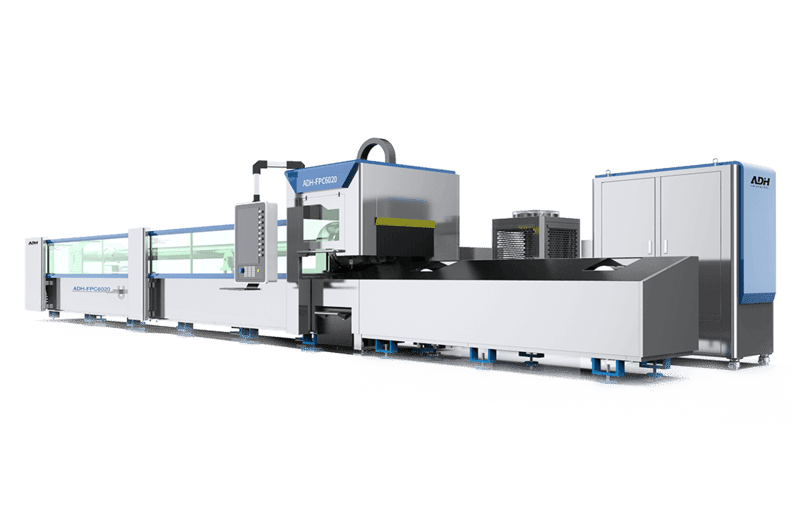

Tube Laser Cutting

FPC Series

The FPC2060 is a cutting-edge laser machine designed for precision tube cutting. Its innovative structural design enables it to achieve high-speed cutting while maintaining exceptional precision and stability. This advanced machine features dual pneumatic drive and four long-route claw clamps, allowing for rapid loading and tube changes. With these cutting-edge features, the FPC2060 is an ideal choice for sheet metal fabrication and other precision manufacturing applications.

• Pipe Dimensions : Diameter: 20mm-200mm

Length: 6m/9m (320mm Optional)

• Tube Category : Round,Square,Oval,Rectangular,Triangle,ect.

• Laser Power : 1000W-6000W

• Maximum acceleration : 0.8G

• Rotary Speed : 80r/min

• Positioning Accuracy : ±0.05mm

• Repositioning Accuracy : ±0.05mm

• Total Weight : Over 13T

• Total Power Consumption : 18.3KVA-41KVA

• Power Supply : 380V50Hz/380V60Hz/220V60Hz

Precision Laser Cutting

ULJM Series

This machine integrates laser technology,precision machinery,electronic technology,and computer science to provide high-tech performance It uses the latest electronic technology for faster perforation speed,finer processing quality,superior processing quality,and minimal heat-affected zone. The innovative back-reflection isolation technology enables uninterrupted processing of various high-reflective materials such as copper and aluminum without damaging the laser or causing an alarm.

• Input power : 1000-3000W

• Mainframe size : 1200*1200*2200mm

• X-axis travel : 100-315mm

• Y-axis travel : 535mm

• X/Y axis repeat positioning accuracy : ±0.01mm

• Worktable precision : <0.01mm

• Cooling method : External water cooling

• Transmission mode : Linear motor+0.5 um grating ruler

• Cutting thickness : 0.1mm-4mm

• Processing speed : 20m/min

Established in 1982, ADH has become a hallmark of precision and innovation in the machinery industry. Over four decades, we’ve seamlessly merged traditional craftsmanship with modern technology, offering state-of-the-art products like press brakes, panel benders, and laser cutting machines. Our team, comprising over 600 professionals, operates from three major production bases, ensuring every ADH product meets the pinnacle of quality. Trusted by 50,000+ customers across 30 countries, our global presence is backed by an extensive network of offices and service outlets. With a strong commitment to research, development, and sustainability, ADH isn’t just a brand; it’s a legacy of machinery excellence, continuously setting industry benchmarks.