Machining Center

‾‾‾‾‾‾‾

Vertical Machining Center

VMCII Series

The VMCⅡ series is fixed by A-shaped single column, with mobile structure of worktable, compact overall structure and small floor space and with the design and manufacture conforming to ISO and can complete milling, boring, drilling, tapping and other processes under one clamp. It is configured with standard 8000rpm belt spindle suitable for automobile parts, plastic machinery, construction machinery and other fields.

• Specifications cover VMC760Ⅱ/850Ⅱ/1000Ⅱ/1200Ⅱ.

• High rigidity

• High vibration resistance

• High precision

• High thermal stability

• High dynamic response

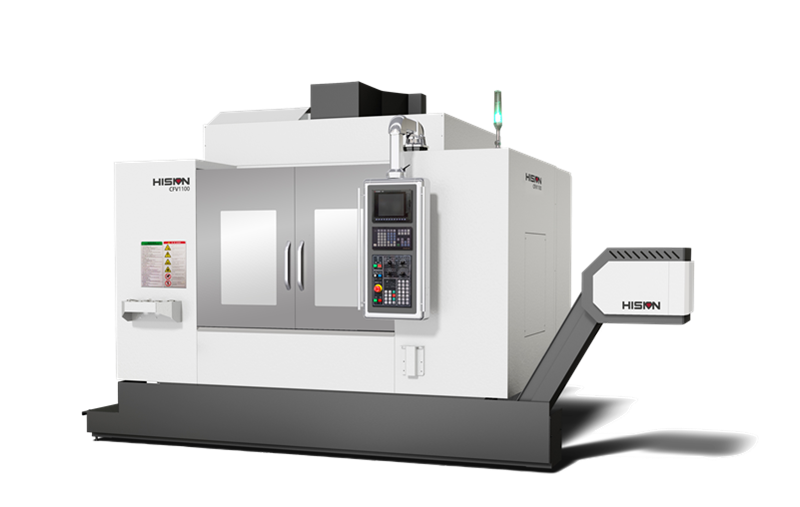

Vertical Machining Center

CFV Series

The CFV series is fixed by A-shaped single column, with mobile structure of worktable.The rigidity of the basic components is high and the mobile components are light, fully conforming to the needs of users. Meanwhile, it is characterized by the environmental protection and energy saving, therefore widely used in high-efficiency and high-precision processing of automobiles and dies, etc.

• Specifications cover CFV600/900/1100

• Configure advanced motorized spindle

• The rigidity of the basic components is high

• The mobile components are light

• Driving system with high dynamic response

Horizontal Machining Center

H-Series

The heavy-cutting high-rigidity rectangular-guide horizontal processing center for H series is a machine tool structure which integrates international advanced design concept and is more suitable for heavy cutting of large parts. It adopts ultra-wide guide structure and is famous for its wide processing range. Product application areas: mechanical processing in the automotive, petroleum, electric power, locomotive, plastic machinery, engineering machinery and other industries.

• Specifications cover 63H/80H/100H/125H

• High-power high-torque full gear box structure spindle

• High-precision large load bearing worktable

• Safe, convenient and efficient double pallet changer

• Excellent chip removal ability

• Stable and reliable tool exchange system

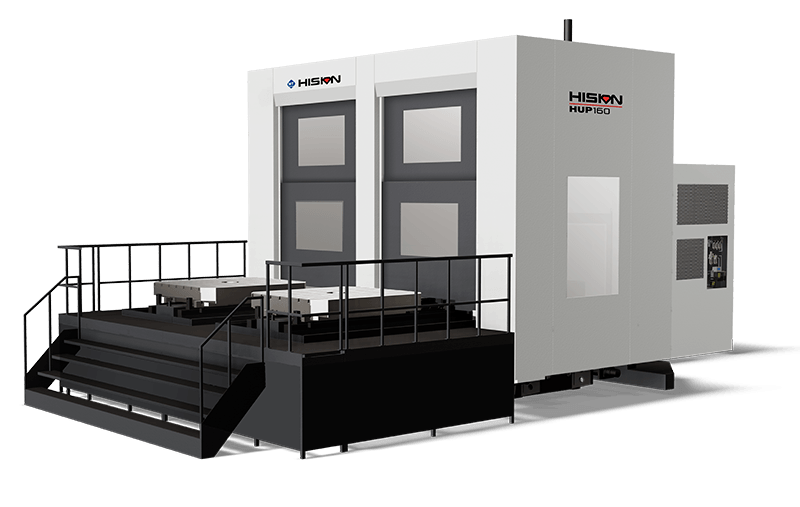

Horizontal Machining Center

HUP Series

HUP series high rigidity roller guide horizontal machining center. Modern design with advanced international perspective. T-type machine bed, with hanging box layout. 3-axis high rigidity roller guide brings about perfect balance between high precision and high efficiency. It is applicable for a wide variety of rough and finish machining.

• Specifications cover HUP80/100/125/160

• High-power high-torque full gear box structure spindle

• High-precision large load bearing worktable

• Safe, convenient and efficient double pallet changer

• Stable and reliable tool exchange system

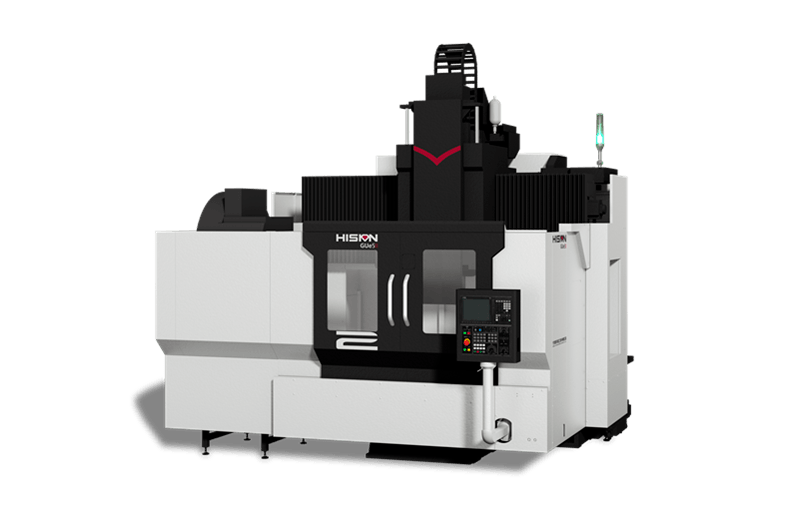

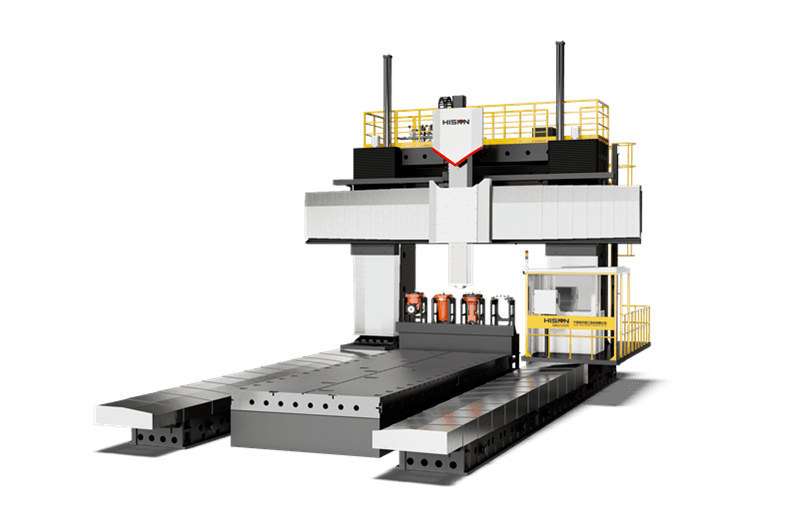

Double Column

Double Column

Products adapt to the characteristics of the traditional double column machines with high rigidity, symmetrical structure, high stability. Through element analysis, optimizing the structure of basic components and improving the dynamic performance of the product we obtain the perfect combination of high power, high torque, high efficiency and high precision processing. It is suitable for large and heavy processing fields such as shipbuilding, metallurgy, petrochemical, mining machinery, electric power energy, plastic machinery, engineering machinery…

Fix Cross Rail DCMC

Double Column

Adapting to the structural characteristics of traditional gantry products with strong rigidity and wide processing range, integrating advanced technical elements and pursuing the development concept of high efficiency, high precision, energy saving and amenity. Widely used in mold, aviation, rail transit, automobile, household appliances, medical and other high-end manufacturing industries.

FIVE-FACE DCMC

Double Column

Products adapt to the characteristics of the traditional double column machines with high rigidity, symmetrical structure, high stability. Through element analysis, optimizing the structure of basic components and improving the dynamic performance of the product we obtain the perfect combination of high power, high torque, high efficiency and high precision processing. It is suitable for large and heavy processing fields such as shipbuilding, metallurgy, petrochemical, mining machinery, electric power energy, plastic machinery, engineering machinery…

CROSS RAIL FIVE-FACE

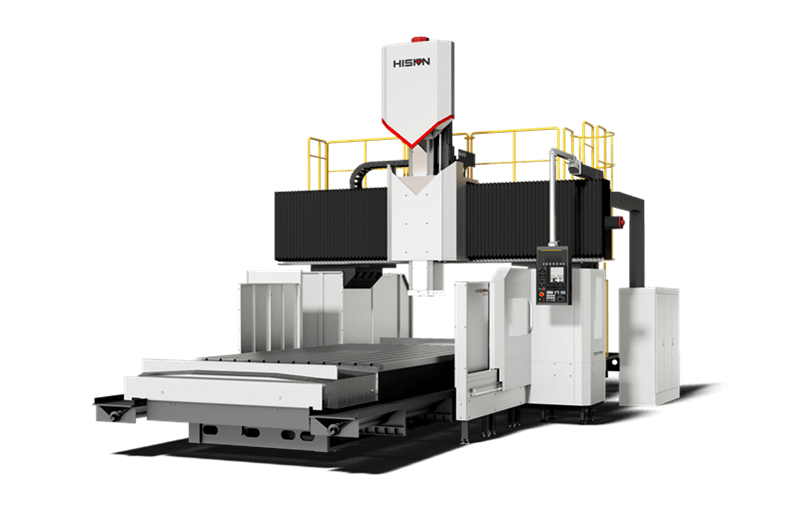

Double Column

Gantry framework whole gantry milling and boring machine inherited the characteristics of the traditional gantry machine with strong infrastructure rigidity, symmetrical structure, strong stability, on the basis of an innovative design concept. All products using PRO/E 3D design, main machine structure adopts finite element analysis, by optimizing the distributed structure, reasonable distribution of quality, make the machine with strong rigidity, better dynamic characteristics and meet the requirements of high power, high precision cutting. Suitable for large parts processing in various mechanical processing fields such as ship, new energy, automobile, engineering machinery, packaging, rail transit, hardware and rubber, etc.

Ningbo Haitian Precision Machinery Co., Ltd. is a listed company specializing in machine tooling industry. It has developed Ningbo Dagang production base, Ningbo Yanshan production base,Dalian production base and Ningbo high-end CNC machine tools intelligent production base. It has a modern constant temperature processing and assembly plant of over 500,000 square meters with nearly 1900 employees. It is awarded honors such as“national major technical equipment enterprise”, “national high-tech enterprise”, and “provincial high-tech research and development center”.